Nozzle

New product

M Nozzle, MN-S73G, Zinc-plating spatter countermeasure dedicated nozzle

Spatter peeling off with zinc-plating steel easy!

| Surface Treatment | Life Time Performance | Cost Comparison | Spatter Peelability |

| Plating Nozzle | 1.0 | 1.0 | × |

| Magby Treatment | 1.5 | 2.1 | △ |

| M Nozzle pX | 2.5 | 2.7 | 〇 |

| M Nozzle GX | 4.5 | 2.7 | ◎ |

M Nozzle NEW

Characteristic

・Compatibility nozzle with conventional type in a revolutionary spatter adhesion prevention coating

・200A 350A 500A 600A Available in each current range

・Conventional Nozzle→Spatter (About 1000℃)adheres to the nozzle, operate mechanical peeling (Damaged with scratches)

・M Nozzle→Spatter adheres to the nozzle, easy peeling off with cloth etc. (Less scratches)

SKK Nozzle NEW

Characteristic

・Standard compatibility Nozzle of low cost, uniform beautiful plating quality.

・Φ21 is recommended for robot operation

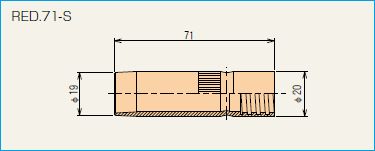

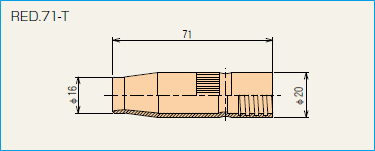

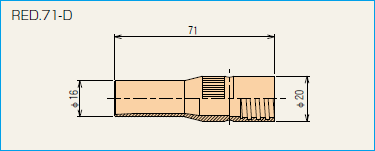

RED.71 Nozzle

CharacteristicDue to thin thickness of Tip portion, the spatter adhered area is reduced and the spatter is hard to adhere and also easy removal even if adhered.

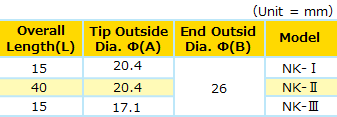

Specification |

|

|

|

|

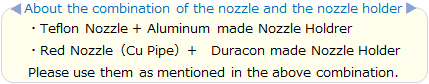

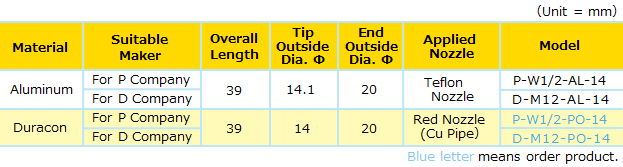

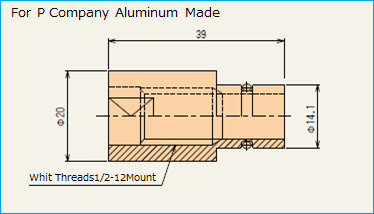

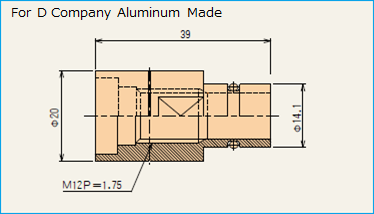

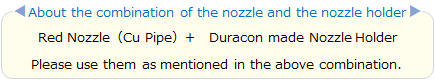

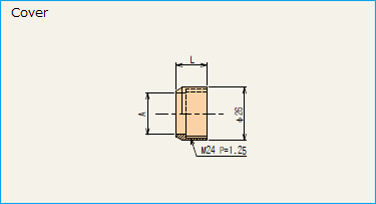

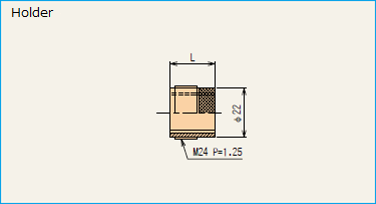

Nozzle Holder (Aluminum Duracon Made)

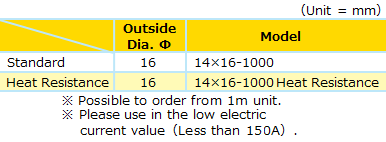

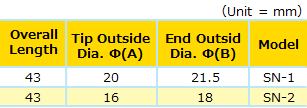

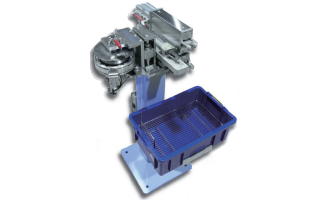

Teflon Pipe Nozzle

Characteristic・Hard to adhesion of the spatter. ・Together us with Specialized Aluminum Adapter. ・Cutting is made free, according to the necessary length. ・Soft material is strong for the interference with work.

|

|

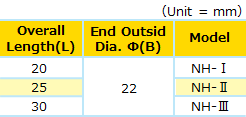

Spacification |

|

Red Nozzle(Cu Pipe)

CharacteristicDue to Small Diameter, it is suitable for a difficulty of an interference with Jig.

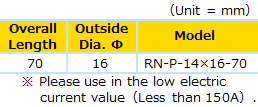

Spacification |