Basis and Point of Resistance Welding (2)

4. Correct choice of the electrode of the spot welding

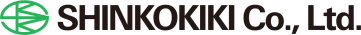

The ideal electrode material is a high strength material which wi be able to be endured a high strength material having high hardness and endurance against the deformation pressure under high temperature securing the high thermal conductivity and electric conductivity. However, it means to seek the material of conflicting quality physically and it is not exist the material provided with both functions. Accordingly, it is reality to use them corresponding to the purpose. In the case of the galvanized steel sheet welding which will become higher the temperature of tip portion electrode, the selection of the electrode emphasized the thermal conductivity. In case of high tension steel sheet and stainless steel sheet emphasized the pressure condition, the hardness of the room temperature.

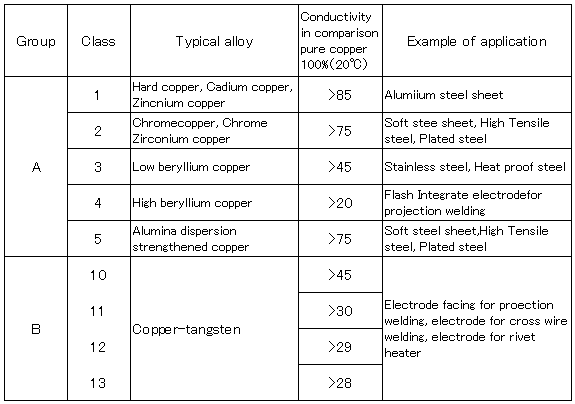

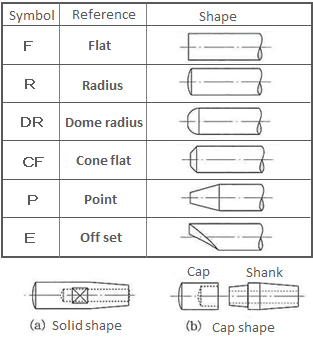

The pay attention to the tip shape of the electrode is not only the nugget formation. It is important examination items of the electrode about the necessity thermal capacity which is hard to deform when the heat is efficiently transmitted and the volume of self-adjustment operation of the difference from expulsion limit current. It means that the self-adjustment operation is the prevention of the occurence of welding expulsion, when the current path is expanded biting of the tip portion of the electrode to the plate. The electrode of the radius shape of the spherical surface of the large curvature radius has large action and the expulsion limit current is increased largely due to increase of pressurizing force.

The electrode of radius shape of tip portion is considered to be unsuitable for the spot welding of the galvanized steel sheet which is narrow welding condition range due to the reason of large variation width of the current path. However, the increase of biting amount of the tip portion of the electrode is occurred by the softened plate surface of the temperature rise of the fusion zone. Therefore,it will be considered as preferable changefro the prevention of uneven heating of the fusion zone. In fact, the DR ( dome・radius ) electrode which is superior to the nugget formation having about R40 radius shape of tip portion f the electrode. As its electrode has large thermal capacity and has excellent electrode shaping by the tip dresser, it is recognized as main electrode of almost of all body factory of automotive makers.

Due to want of page space, we take liberty to omit the wear form of the electrode or the approach to the cooling system. As a specialized maker of the electrode for the welding, we are trying to response to our customer’s question or requirements through every opportunity.

(4-1) Function of the spot welding electrode and desired quality

(4-2) Shape and material for electrode using spot welding

|

(4-3) Difference of expulsion of demarcation current caused by self-adustment of electrode

|

(Fig・10) Influence by variation of the electrode tip ed shape on marginal codition for expulsion |

|

R type electrode havig self-adjustment facility will extend contacting diameter larger by influence of increase of pressure etc and increase explosion and flash of demarcation current. |

5. The determine method of the spot welding condition

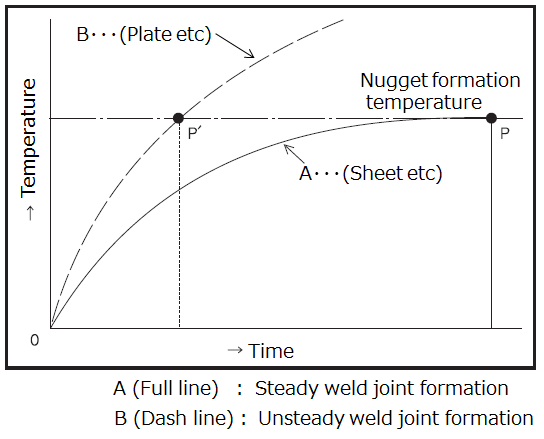

(5-1) Study on welding condition related with thermal quality

(5-2) List of soft steel sheet spot weldig condition

(5-3) The welding condition led to the combination of sheet thickness and electrode shape

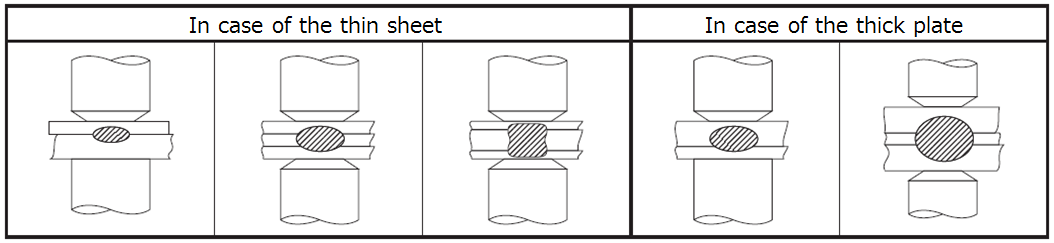

(Fig・12) The combination of sheet thickness and electrode shape

(Fig・12) The combination of sheet thickness and electrode shape

When the thin sheet and the thick plate are spot welded it is better to set up the weldig condition base on the criterion of the smaller thermal volume. However, the influence of the thermal volume of electrode is bigger than the steel sheet, it is set up the welding condition as a base of the thick plate contact to the side of small thermal volume convex shape electrode.

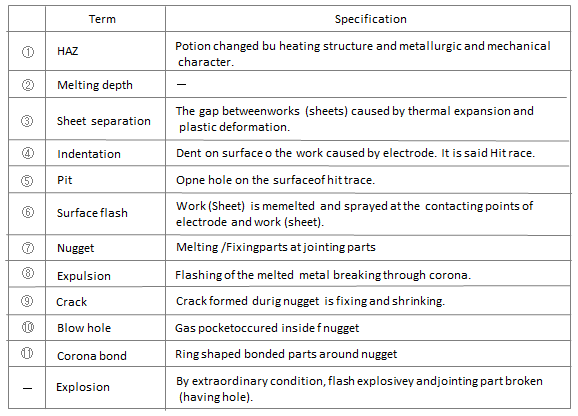

【 Appendix:Word and terms on spot welding parts 】

|

(Fig・13) Cross section at spot welding parts |

|