Basis and Point of Arc Welding

Recently, We have been made of the [ Arc Welding Techinical Lecture ] to the Automotive Parts Makers and the other various customers.

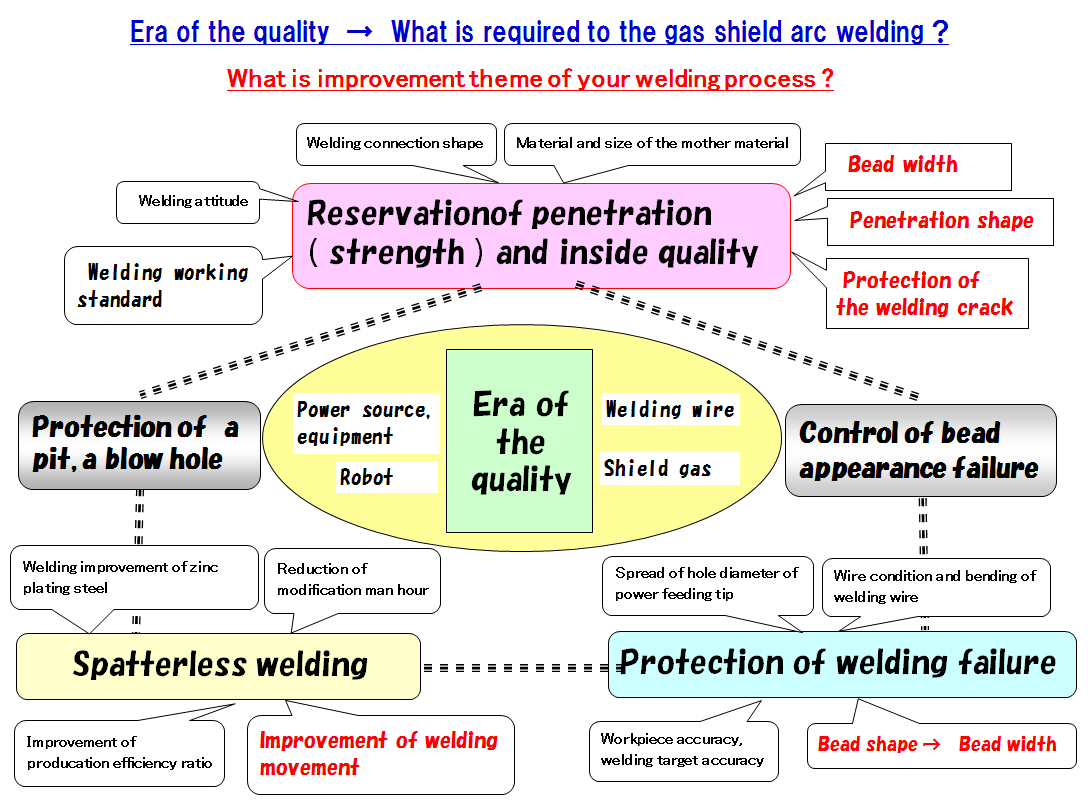

In these lectures, there are many [voices] from the customers is that [ never leak the [ quality failure] and if its leakage is made, is fatal mistaken to the company. Although it is said very long time to be said as [ the era of quality] , as you know well, the arc welding has the problem , such as, scattering of the Spatter, the surrounding of the welding machine are hard to keep clean condition by the occurance of fume. Also, the welding is made of power supply through the contact tip with high speed by the small diameter welding wire and there are many welding control condition with difficult quality control and improvement due to dispersion of the circumstance. This is very difficult theme to solve or improve.

Accordingly, it is highly appreciated if you take into your account to do your daily work keeping into your mind about [three major basis] of the arc welding , i.e., the two large major influence factors of the welding quality through site advice or welding engineering lecture etc.

■ Three basis of the welding quality

① Smooth wire feeding

② Reliable power supply of the welding wire

③ Calm covering gas supply to the welding portion.

These three basis are closely related to the welding machine, welding wire and shield gas. These specifications are different to each customers and the welding products are also required the different characteristics. However, as a axis of three basis, it is common procedure to welding process and the assembly the welding work. We would like to be highly appreciated if you are corresponding as a reference disclosed our example.

■ Two major factors to have influence to the welding quality

① Separation of weldng wire・・・wire beding way, twist of conduit pipe, enlargement of tip top hole etc.

② Spatter・・・bead appearance failure, blow hole etc.

These two factors are very close relation to the welding failure and will be connected the most important [Welded trength] in the welding quality. Your careful attention from the initial production preparation to the daily welding work is highly appreciated.

When we can get the opprtunity to observe your welding site, the most important feeling is that the fundamental principle of qualiy acquisition is 4S of the welding jig surrounding place. If you keep the welding process place to be clean condition, the welding process which will be easy to make dirty condition by tha spatter, the fume or the soot will become [ Visualization ] of the welding failure factor. Your active development of daily activity is expected.

If the standardized welding work is carried out as per the [ Welding conditon instruction ] , the maintain and improvement of quality will be accelerated. As mentioned in the word of [ Standardized process ] , it is important to keep or to be kept the process and at the same time, daily originality idea, result of improvement is fed back to the instruction. The discussion of improvement added to the original idea is very useful for your improved working situation.

In the [ Welding Engineering News } , we would like to introduce from the basic knowledge to the various valuable lesson relayed on our long years welding improved process experience gained by the actual workig fields of the engineering service to the various customers.