1. Let’s learn about welding!~Resistance Welding~

2024/07/03

Kyappa-kun is a cap tip that was born in Shinkokiki’s own factory.

As a newborn, he is very interested in welding.

Let’s learn to weld with him.

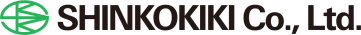

【Classification and Types of Welding】

There are many types of welding, as shown in the figure.

Among them, we will learn about resistance welding in this issue.

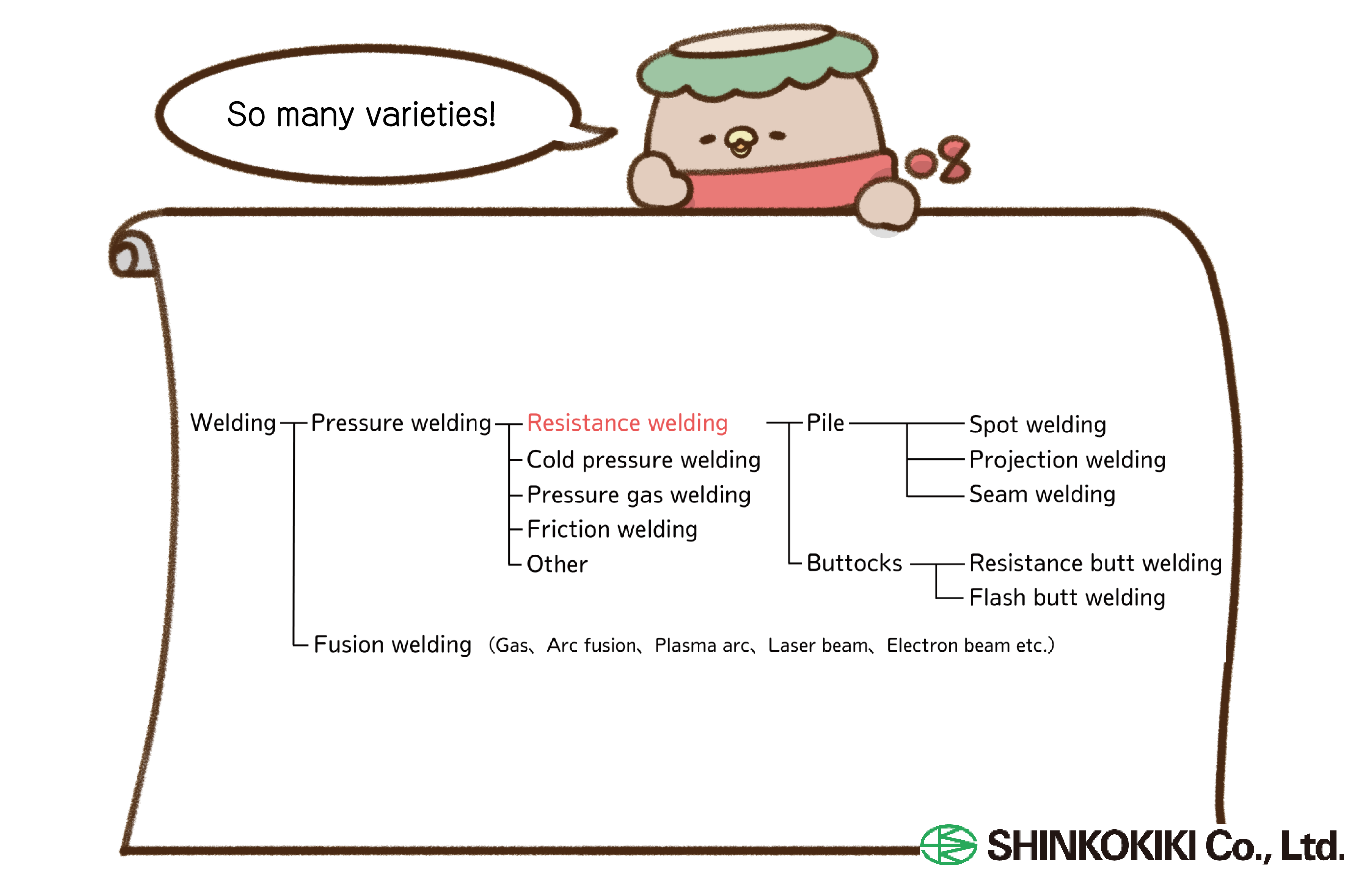

【What is resistance welding?】

Resistance welding is a welding process used to join steel plates together.

When two steel plates are overlapped, moderate pressure is applied to the area to be welded, and an electric current is applied, the plates melt and adhere to each other due to resistance heat generation.

The melted and bonded portion is called the nugget.

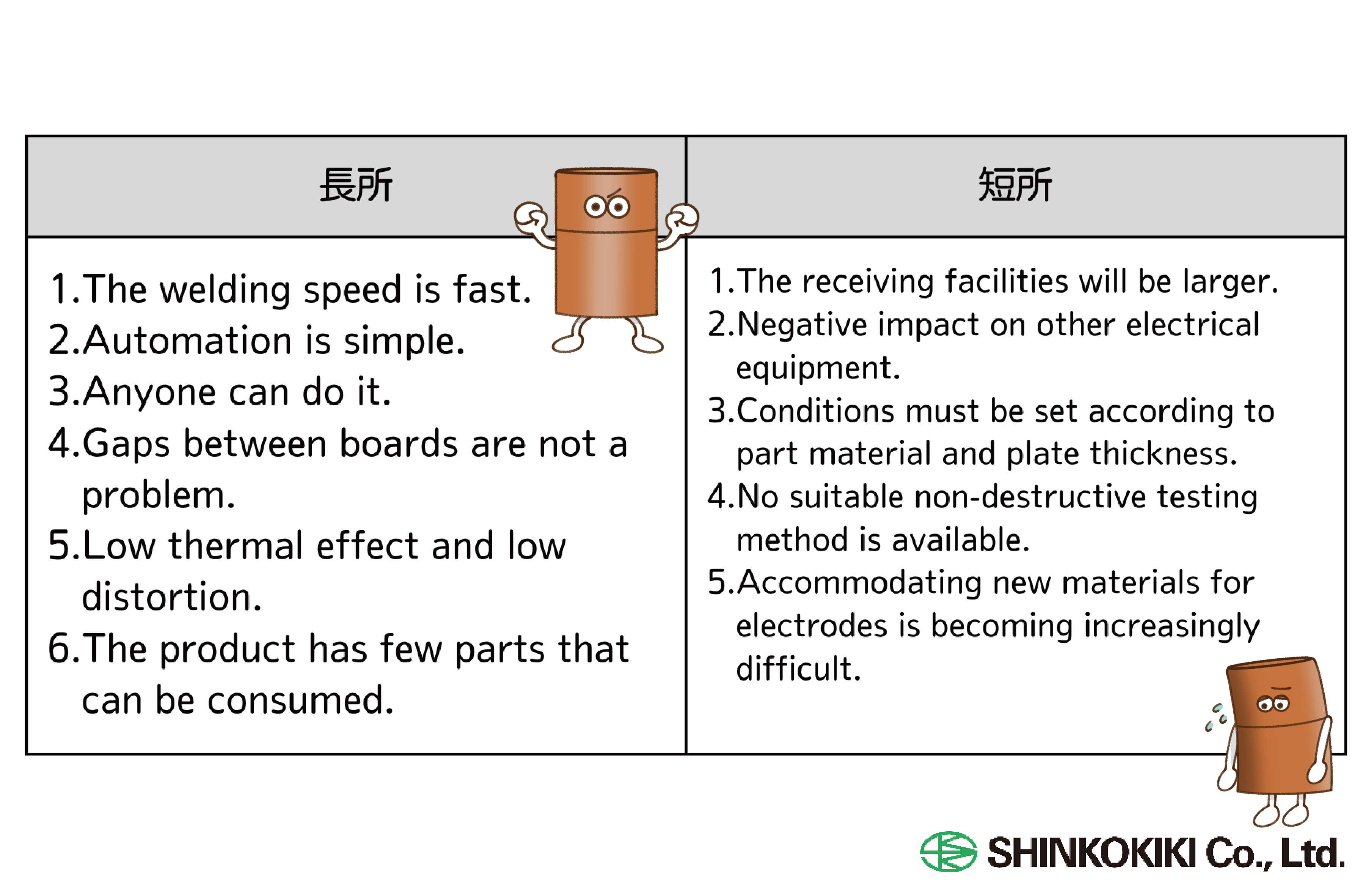

【Pros and cons of spot welding】

There are several types of resistance welding, the most typical of which is spot welding.

Spot welding is ideal for thin plate welding and electrode control is very important.

Let’s take a closer look at the features.

【What is an electrode?】

Electrodes are essential for conducting electrical current and generating resistance heat.

Electrodes used in resistance welding are primarily made of copper alloys.

Copper alloys are utilized due to their ability to withstand high pressures and temperatures, as well as their consumable and stable nature. They are also easy to process and cost-effective.

Electrodes are generally,

Chromium copper

Chromium zirconium copper

Alumina dispersion strengthened copper

are generally used.

Chrome copper is a widely used material.

Chrome zirconium copper is more durable than chrome copper, which is also commonly used. It is a harder material.

Alumina dispersion strengthened copper is utilized in severe welding conditions because of its excellent heat resistance.

Beryllium copper is an infrequently utilized material.

Our products primarily use Chrome Zirconium Copper and Alumina Dispersion Strengthened Copper.

That’s all for this time.

See you in the next column!