7. Let’s learn about welding!~Welding type~

2025/03/21

Previously, Kyappa-kun learned about bolt welding.

This time, let’s explore other types of welding, including what we’ve learned so far!

【What is Welding?】

Welding is the process of joining materials, such as metals, by melting them together. Some of the most common types include [Resistance Welding] and [Arc Welding], which we have learned about so far.

Surprisingly, welding is widely used in our daily lives. It plays a crucial role in manufacturing bicycles, cars, refrigerators, washing machines, and many other everyday items. Welding technology is an essential part of modern life!

【Various Welding Methods】

Let’s take a fresh look at the different types of welding methods, including those we’ve learned so far.

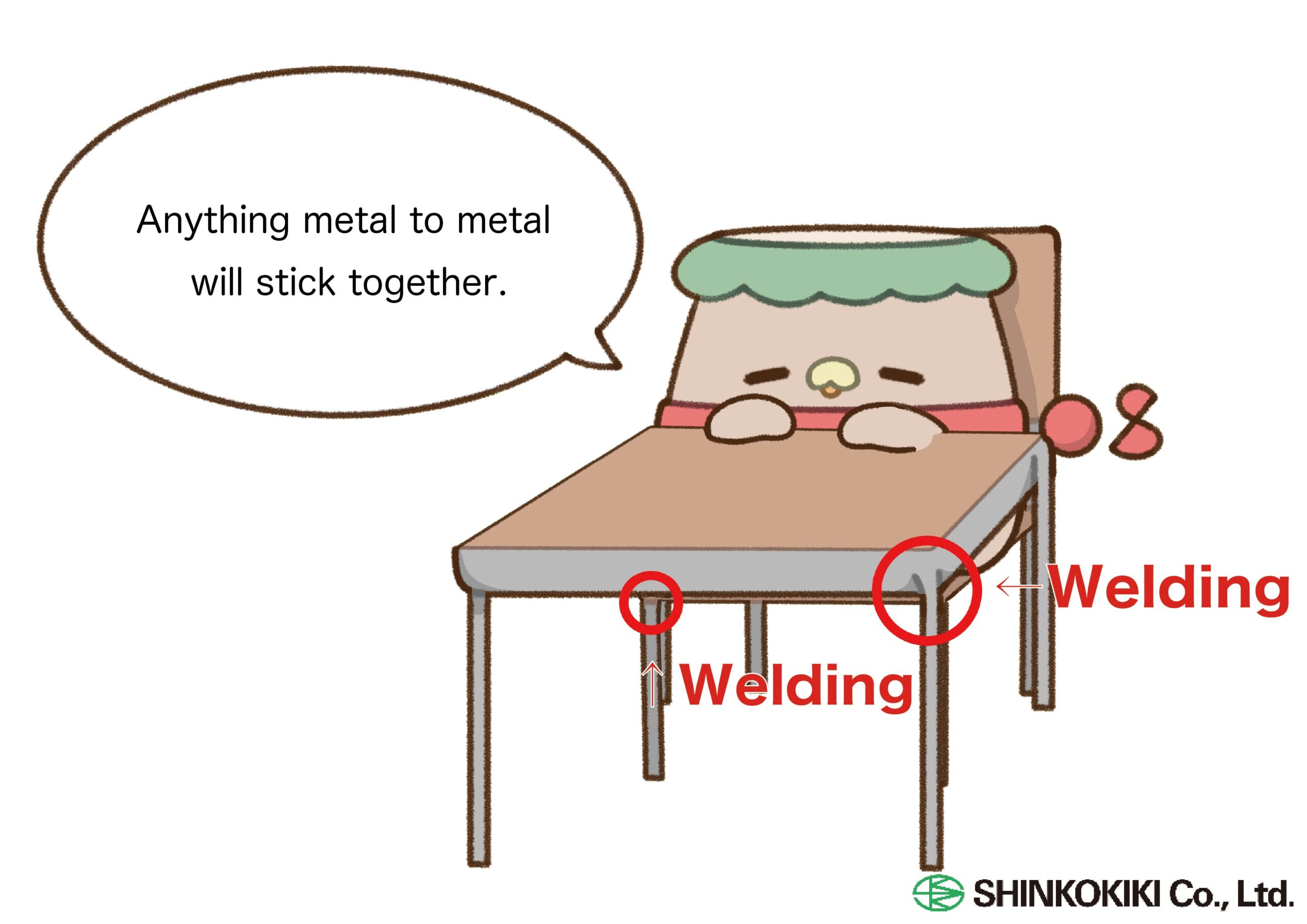

★ Resistance Welding

This method involves overlapping two metal pieces and clamping the welding area between electrodes. An electric current is passed through while applying pressure, utilizing the Joule heating effect to fuse the metals together.

● Spot Welding

A type of Resistance Welding used to join metal sheets together.

● Projection Welding

A type of Resistance Welding that joins protruding parts, such as nuts or bolts, by melting them.

The key difference from Spot Welding is whether the material being welded has protrusions or not.

● Seam Welding

A type of Resistance Welding, also known as Stitch Welding. As the name suggests, it performs continuous welding, similar to a sewing machine.

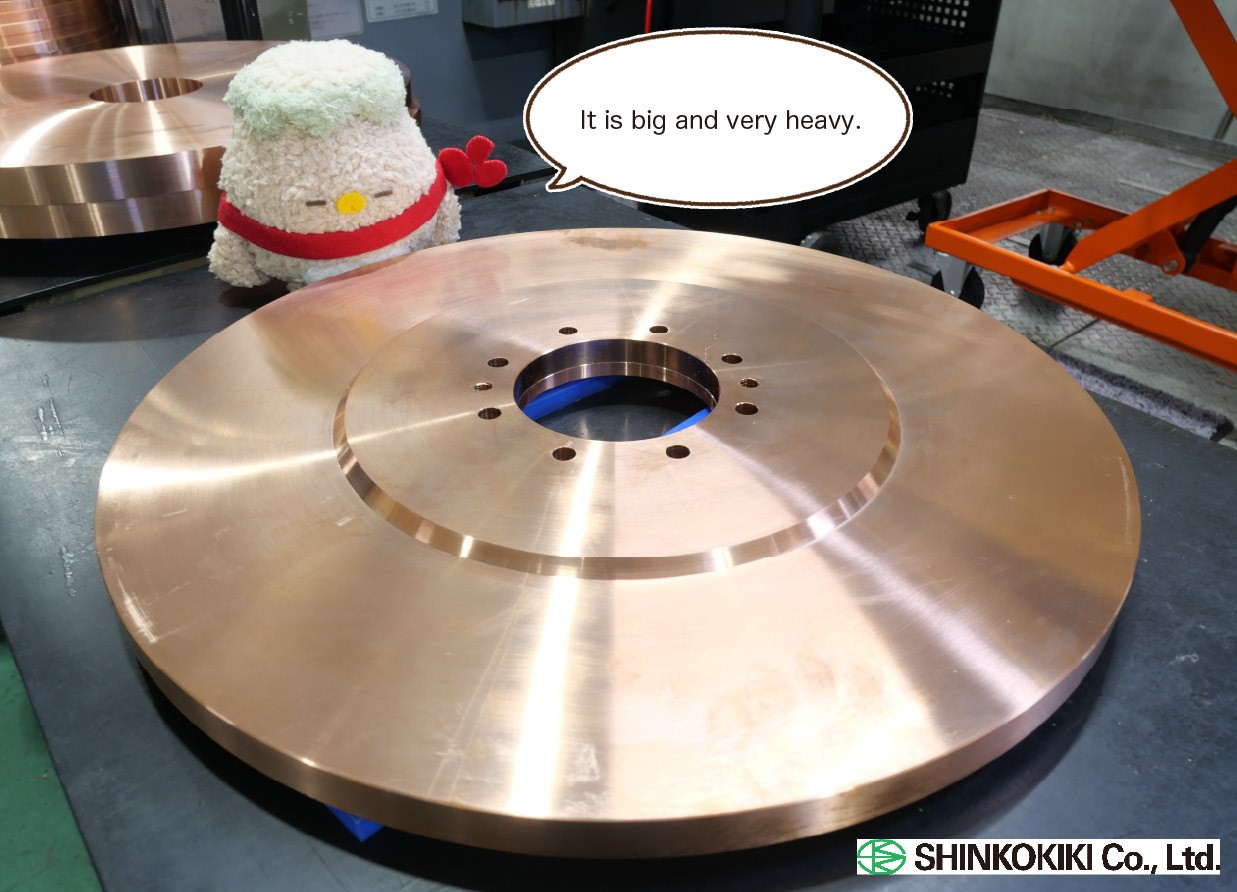

This method uses disc-shaped electrodes to clamp the material and rotates them like a wheel to create a seamless weld. Some large disc electrodes can have a diameter of up to 55 cm!

Seam Welding is used for products that require high airtightness, such as fuel tanks and gas cans.

★ Arc Welding

A welding method that utilizes an electric discharge phenomenon in the air to fuse metals together.

● MAG (Metal Active Gas) Welding

A type of Arc Welding, where “MAG” stands for Metal Active Gas. This method uses both a Wire Electrode and a shielding gas.

The shielding gas prevents atmospheric contamination during welding by protecting the molten metal from air exposure, which could cause defects like bubbles.

In MAG welding, active gases such as carbon dioxide (CO₂) or a mixture of CO₂ and argon (Ar) are used. It is mainly used for welding iron and mild steel. However, it is not suitable for non-ferrous metals, as they react chemically with carbon dioxide.

● MIG (Metal Inert Gas) Welding

A type of Arc Welding, where “MIG” stands for Metal Inert Gas. This method also uses both a wire electrode and a shielding gas.

Unlike MAG welding, MIG welding uses inert gases, making it suitable for welding both ferrous and non-ferrous metals. It produces less spatter (sparks that fly during welding) and results in a cleaner finish compared to MAG welding.

However, its drawback is that it has poorer penetration compared to other gas welding methods.

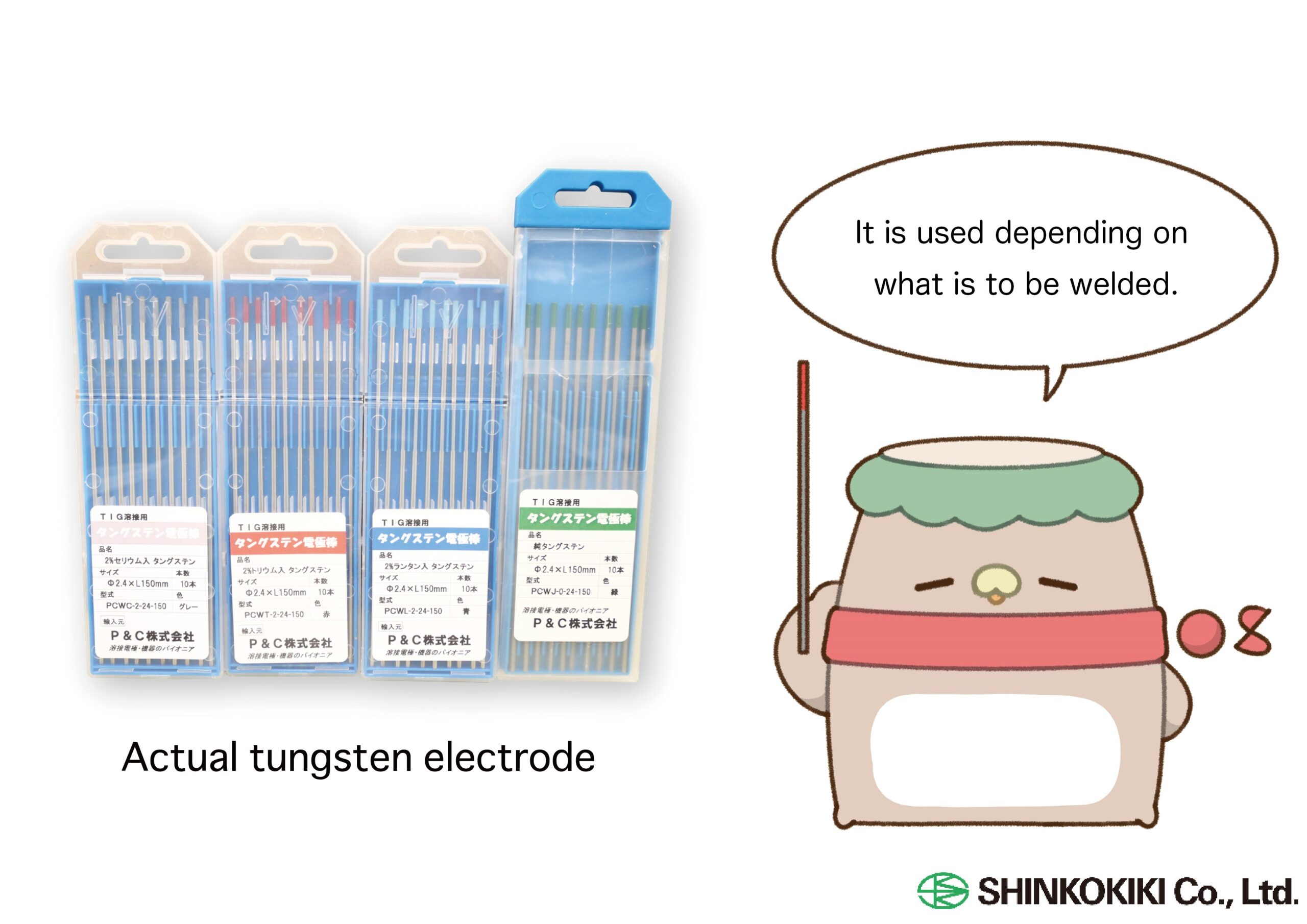

● TIG (Tungsten Inert Gas) Welding

A type of Arc Welding, where “TIG” stands for Tungsten Inert Gas. This method uses a welding rod, tungsten electrode, and shielding gas.

TIG welding employs inert gases like argon (Ar), making it suitable for welding almost all metals, including iron and aluminum. It enables high-quality welding with clean and precise results.

However, TIG welding has some drawbacks:

・The welding rod must be manually controlled, slowing down the process.

・Both hands are required, making it more technically demanding.