3. Let’s learn about welding!~Combination~

2024/08/21

Last time Kyappa-kun learned in detail about electrodes.

This time, let’s learn about the parts other than electrodes that are used in resistance welding.

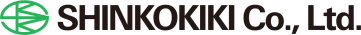

【Names and Combinations of Parts】

In a typical spot welding setup, the parts typically consist of a cap tip, a shank, and a straight holder, as shown in the diagram.

Next, let’s explain the shank.

Our company’s shanks are made from beryllium copper. This material is used to prevent sticking between the different parts we learned about last time. Additionally, beryllium copper is known for its high strength and durability, making it suitable for withstanding the impact during pressing.

While a standard shank is a “straight shank,” for welding irregularly shaped workpieces, such as U-shaped ones that can’t be handled by a straight shank, an “offset shank” is used.

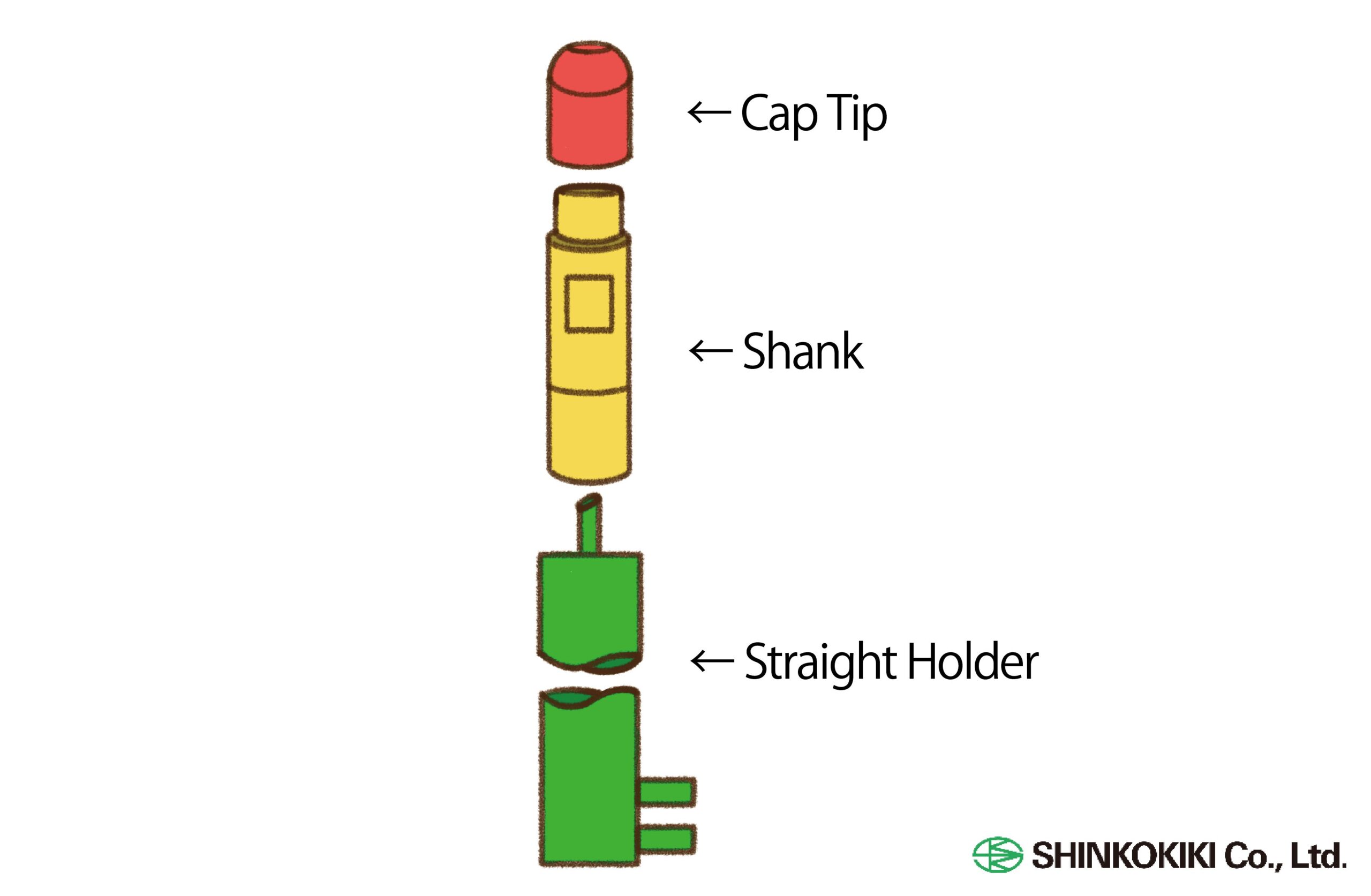

A common method for combining welding parts is the use of tapers. A taper is a shape that gradually narrows, like a cone. This method is applied to each part to help them fit together.

Traditionally, parts could only be combined if they had the same standard diameter and taper. That’s where the “switching holder” comes in. With a switching holder, you can easily switch between different tapers and combine parts that have different tapers by inserting the switching holder in between!

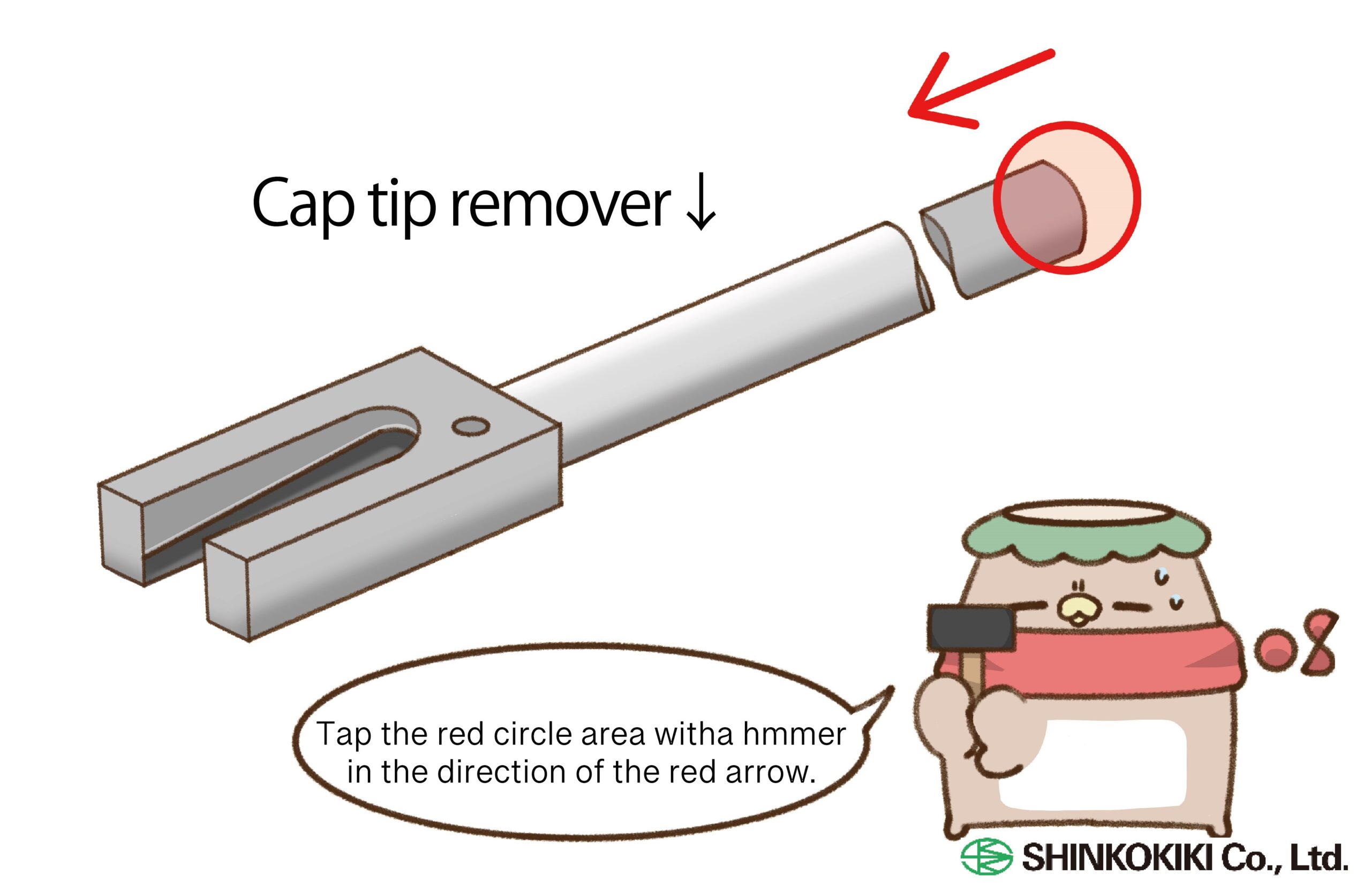

【Replacing Electrode Parts】

Copper and copper alloys used for electrodes have relatively low hardness, so they can be removed easily and safely with a specialized removal tool rather than forcing them off. Our company sells a “cap tip remover” as a dedicated tool for this purpose. Using this tool, you can remove the cap tip and shank without damaging the taper parts.

That’s all for this time.

See you in the next column!