Lesson 10: Let’s Learn About Welding – Materials Edition

2026/01/20

Last time, Kyappa-kun learned more in depth about technical drawings.

This time, let’s move on to studying materials.

[What are electrodes made of?]

Electrodes are essential components in welding and are also one of our main products. In particular, cap tips have a distinctive glossy reddish color, and they are made from copper alloys.

A copper alloy is a material in which copper is the primary element and other metals are added to create an alloy.

Our cap tips are made from various types of copper alloys, allowing you to choose the most suitable type based on the workpiece and other conditions.

[What kind of metal is copper?]

Let’s start by learning about copper.

● Excellent electrical conductivity

Copper has the second-highest electrical conductivity among metals, following silver, and is widely used in electrical components.

Because of this extremely high conductivity, copper is also used as a material for electrodes and other components placed at the tip of welding equipment.

● Excellent thermal conductivity

Similar to its electrical conductivity, copper also has the second-highest thermal conductivity among metals after silver, which is why it is commonly used in cookware.

In welding, this high thermal conductivity is utilized in electrode materials to prevent overheating and to help maintain stable welding performance.

● Good machinability

Copper becomes easier to machine when alloyed, making it suitable for cutting and shaping.

For this reason, it is widely used in products manufactured by machining, such as welding electrodes, gears, and screws.

● Easy to plate and solder

Many of our products made from copper undergo plating processes, as copper is well suited for both plating and soldering.

● Superior Antibacterial Properties

As became widely known during the COVID-19 pandemic, copper has antibacterial properties that can kill various types of bacteria.

Thanks to this characteristic, copper is used in many products such as doorknobs, handrails, and kitchen utensils.

[Copper Alloys Used for Electrodes]

A variety of special copper alloys are used for welding electrodes.

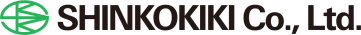

● Heat-Resistant Alloys

As the operating temperature of a metal increases, its strength gradually decreases. Standard copper begins to experience performance issues when used above approximately 150°C, so alloys that maintain strength even at high temperatures are required.

For this reason, welding electrodes commonly use chromium copper, which contains 0.5–1.3% chromium added to copper.

We also offer cap tips made from chromium–zirconium copper, which is produced by adding zirconium to chromium copper, as well as alumina‑dispersion‑strengthened copper, which is made by dispersing alumina into pure copper.

These alloys have higher strength and greater durability than standard chromium copper.

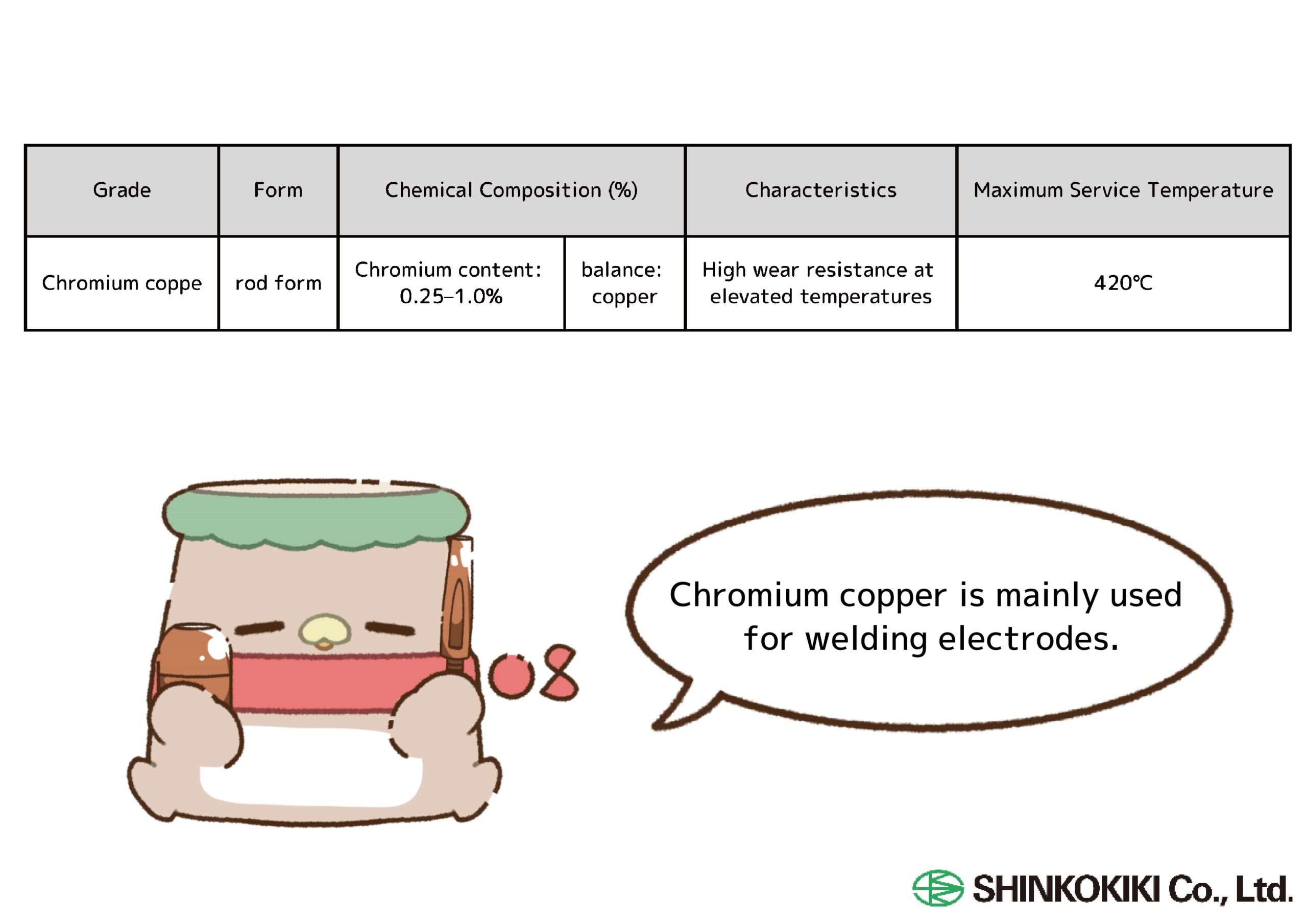

● High-Strength Alloys (Beryllium Copper)

High‑strength alloys such as beryllium copper possess strength comparable to steel materials and are used for components like shanks.

[Other Applications]

Copper is used in a wide range of products—including buildings, electronic devices, precision instruments, and everyday household items—thanks to its excellent workability and corrosion resistance.

Source: Japan Copper Development Association, “Wrought Copper Products”