5. Let’s learn about welding!~Nut welding section~

2024/12/25

Last time, our friend Kyappa-kun learned about projection welding.

This time, let’s dive deeper into the components used in nut welding.

[Let’s Compare KCF and Ceramic Guide Pins]

Previously, we studied the role of guide pins and the differences based on their materials.

Now, let’s take a look at the differences through actual photos.

The image above shows a photo of a KCF guide pin. As you can see, its surface is rough.

KCF guide pins are made of ferritic stainless steel alloy. When this material undergoes heat treatment, an insulating film is formed internally, resulting in the rough texture of the surface.

The image above shows a ceramic guide pin. Unlike the KCF guide pin, its surface is smooth.

Since ceramics are inherently insulating materials, there is no risk of the insulating layer peeling off, allowing for a polishing process on the surface.

Polishing the surface improves wear resistance (making it smooth) and contributes to enhanced work efficiency during welding.

[Upper Electrode Used in Nut Welding]

The upper electrode refers to the electrode located on the top side during welding.

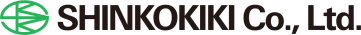

In bolt welding, an F-type tip is used as the upper electrode. Since the bolt has a flat head, it fits perfectly with the F-type tip, allowing for precise and stable welding without misalignment.

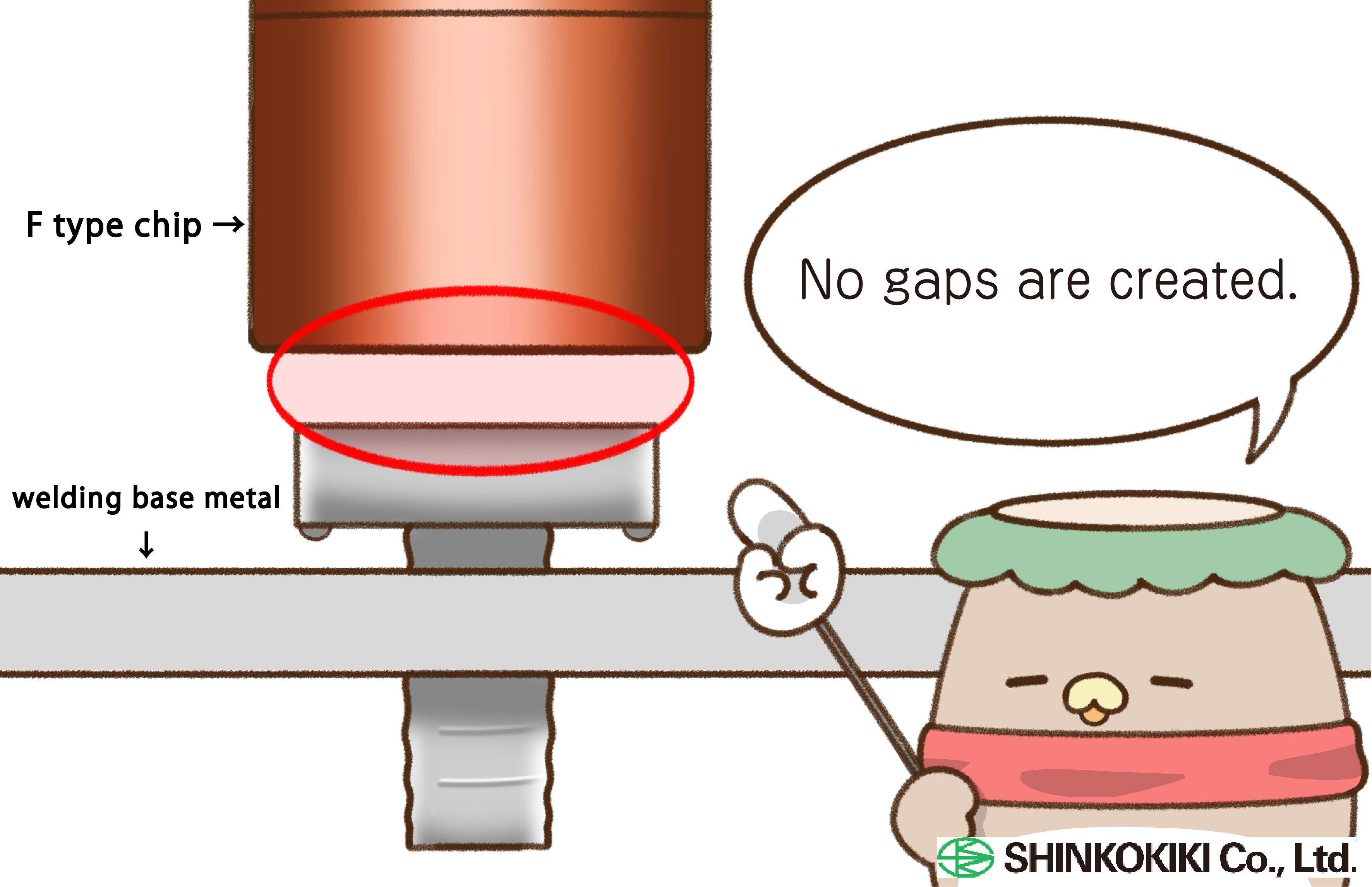

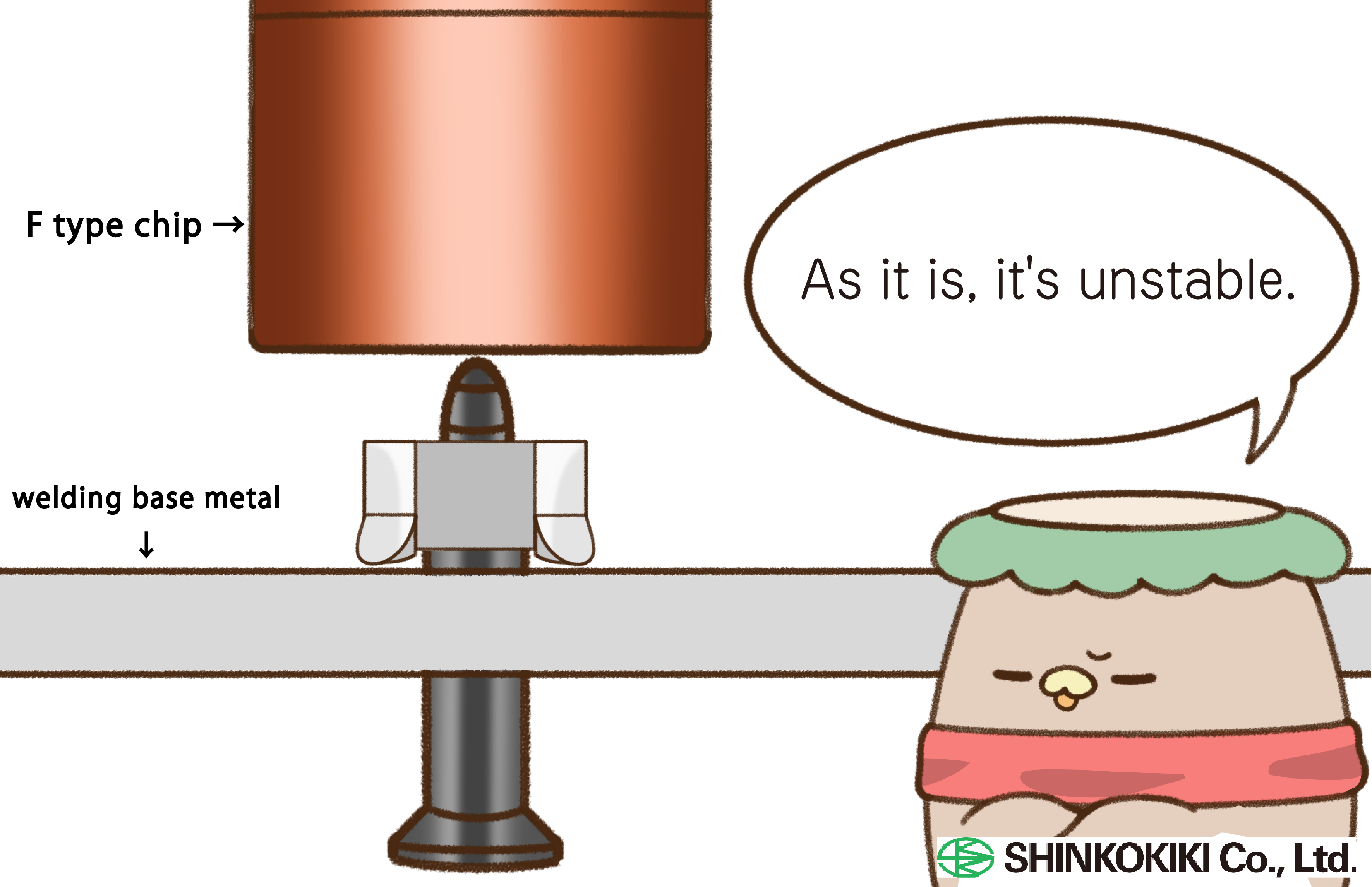

However, in the case of nut welding, as shown in the diagram below, the guide pin protrudes beyond the nut, making the surface uneven. Therefore, if an F-type tip is used as the upper electrode, the guide pin may be pushed, causing the nut to shift from its position, which could result in defective products.

To address this issue, a specialized upper electrode for nut welding is used. This product features a hole at the center of the electrode, allowing the guide pin to pass through without interference. This design prevents misalignment of the guide pin or nut, thereby reducing the risk of defective products.

That’s all for this time.

See you in the next column!